Small drainage system leaks can become massive problems when ignored. Let Dynamic Drains restore and repair the sewer lines in your Brazos Valley home. We have provided plumbing services to the Brazos Valley since 2014 and have a team of licensed and trained professionals you can trust to repair and restore the sewer lines in your home and business.

Dynamic Drains, a team of professionals dedicated to honest communication and high professionalism. Give us a call, we will…

- Inspect your sewage pipes

- Diagnose the problem

- Deliver an upfront quote

- Repair your pipes!

FAQ

Concrete sewer lines were installed in the 1940s through the 1970s for residential and commercial properties in the southern part of the US. They are susceptible to corrosion and dissolving over time due to the corrosive nature of sewer water and root intrusion. The pipe can become very brittle on the top and consequently can crumble if an attempt is made to cut it. Concrete pipes also corrode a lot over time on the inside, thus becoming rough and allowing paper and waste to get hung up. All this corrosion makes it difficult to make repairs, as cutting the pipe cleanly can be impossible even with the right tools. We have been successful with splicing in new pipe on a concrete sewer pipe before but it is only a matter of time before the remaining line will need replacement. There are heavy duty couplings that are made specifically for connecting PVC to concrete pipe and that does make it possible to make a repair.

The main issues with concrete sewer lines are the corrosion of the interior of the pipe and the connection points between the sections. Straight concrete sewer pipes were made in two-foot sections, so every two feet along the pipe there are areas susceptible to root intrusion because the joint between two pipes was made with either tar or other type of sealant that eventually dries out. Aside from root intrusions, these dried out joints can allow sewer water to leak into the ground and allow groundwater to leak into the sewer. The other issue of having only two-foot sections is this allows the pipe sections to become misaligned when the ground swells or shrinks over time with droughts and wet periods.

In conclusion, yes, technically a concrete sewer line can be repaired but it is not a permanent solution and should be done as a temporary measure.

Clay sewer lines are more durable than concrete and more common on older residential and commercial buildings. Clay pipe seems to hold up better over time than concrete, and the interior of the pipe stays smooth over time.

The pipe comes in two-foot long sections and, just like concrete sewer pipe, the issue comes about at the connection points between the sections. Cutting clay pipe is easier than cutting concrete and it is less likely to crumble. The common issue we see with clay pipes is that they are susceptible to cracks from the earth shifting. We have made many repairs on clay sewer lines, but similar to the concrete pipe it is not a permanent repair because they are not ideal in our soil in southeast Texas. Like concrete pipe, there are heavy duty couplings made specifically for connecting PVC pipe to clay and that is what should be used whenever repairing a clay sewer pipe.

Ideally, if the budget allows, it is best to replace clay sewer pipes entirely to eliminate the issues from root intrusion and misalignments from ground shifting.

The best method for repairing or replacing damaged drains under a slab is to tunnel underneath the slab to the issue and not break up concrete from above to access it. There are a couple reasons this is the preferred method in this part of the world.

One reason is because the cost to break up concrete from above is combined with the cost to replace flooring and walls, not to mention the mess it creates inside the building.

Another big reason to tunnel versus breaking concrete is there are many homes built with post-tension slabs. On post-tension slabs, there are large cables under a lot of tension running through the slab and they can not be damaged or cut without causing major issues on the integrity of the slab. The most economical way to access a broken drain below a slab is to tunnel to the problem from the outside of the building. Since the earth that once supported the pipe prior to the slab being poured is removed during tunneling, the pipe must be supported in a different method after the repair is made since you can not pack the dirt back in such a way that would provide the needed support.

Once the repair is made, the pipe and fittings are supported by securing them with hangers to the bottom of the slab with heavy duty all-thread rods and approved support hangers. After all that is complete, the dirt removed is packed back into the tunnel. Our tunnel repairs come with a 5 year warranty against breaks or sags.

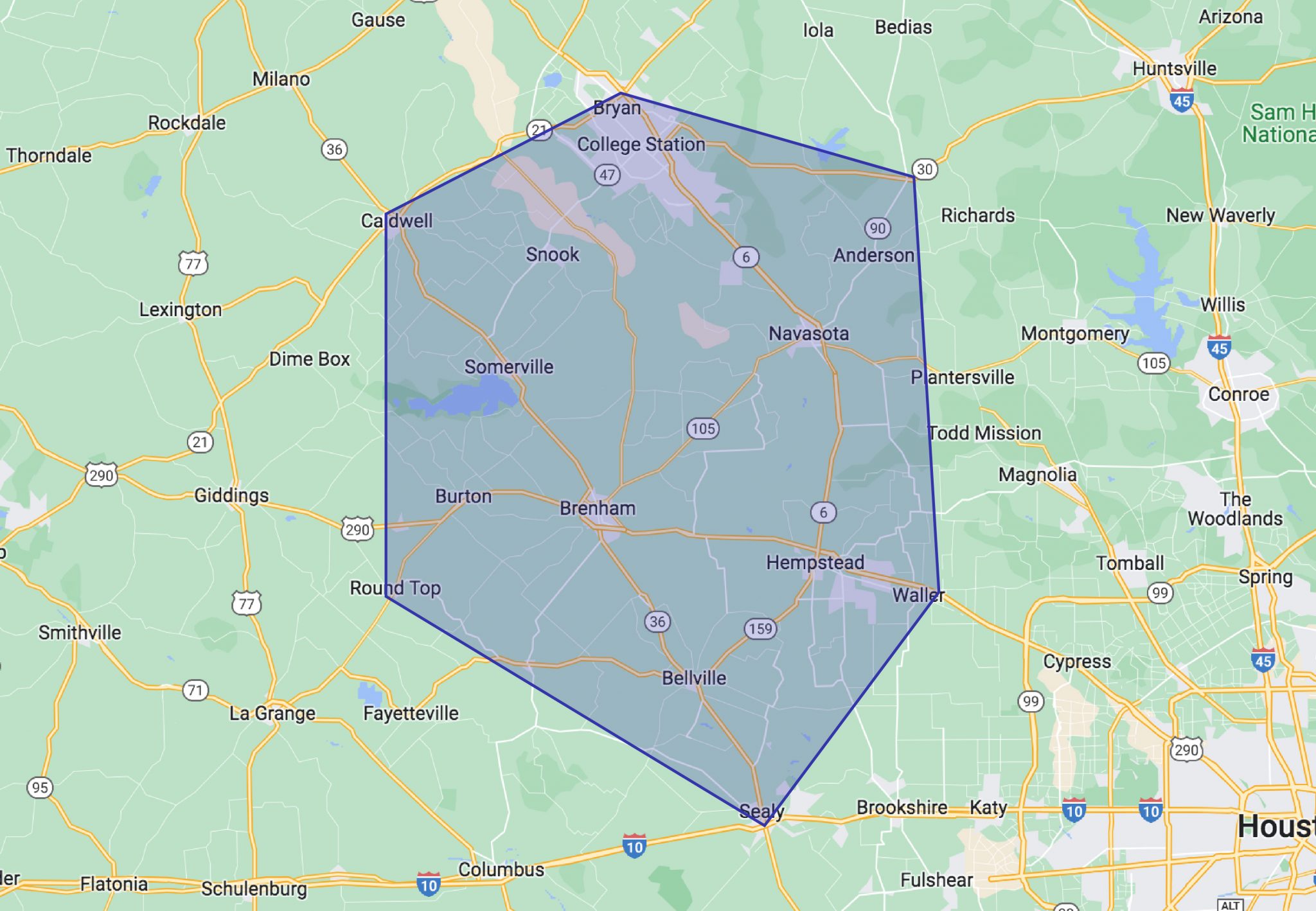

Our Service Areas